The self-driving semi-trucks of the future have arrived – and they’re driving on highways now. At Torc, our autonomous trucks are beyond the research and development of prototypes and moving into our commercialization phase. The trucks that will solve customer needs tomorrow are online and on the road today.

Torc’s self-driving product is powered by both our cutting-edge technology and our rapidly scalable business model. Underpinning it all is responsible and expert use of Artificial Intelligence.

Artificial Intelligence (AI) is a subset of computer science, including deep learning and reinforcement learning, where software is taught to perform tasks for many different applications that would normally require a human touch or direction, like pattern recognition, computer vision, and other forms of decision making. Using AI is especially suited to designing and testing autonomous vehicles, as cutting-edge AI approaches have been shown to deliver the highest accuracy and performance for a vehicle to see, think, and act on the road.

"Training the systems to make decisions through reinforcement learning achieves optimal outcomes.”

– Felix Heide, Head of AI at Torc

AI unlocks the ability for our autonomous driving product to learn to accurately perceive and understand its surroundings, determine what others on the road may do, and safely determine the right actions to take. It ultimately makes our product more reliable and scalable on different road networks in different conditions.

Additionally, our approach to software testing also uses AI, specifically generative AI and neural rendering combined with physics models and techniques. With generative AI, we drastically increase and improve our software’s ability to drive high-volume freight routes, as well as deal with rarely encountered edge cases, allowing our autonomous driving software to experience billions of test miles in a fraction of the time and cost

The Power of Torc’s Virtual Driver

Driving is a skill that people never stop developing. Every time we put the key in the ignition, we learn from our roads and our fellow drivers. We’re constantly tweaking and refining our own driving behaviors with time and experience – and so should our machines.

Enter AI. AI is what powers our software to pick up on changes in the world around it and adjust accordingly, in real-time. For example, whether it’s the ability to pause at a newly installed stop sign or notice construction cones modifying where it is safe to drive, AI powers how the scene is seen and understood, and how the truck should behave, to be the safest vehicle on the road. Its use in self-driving applications cannot be understated. AI can both teach and learn driving skills in less time – specifically what computers were invented to do.

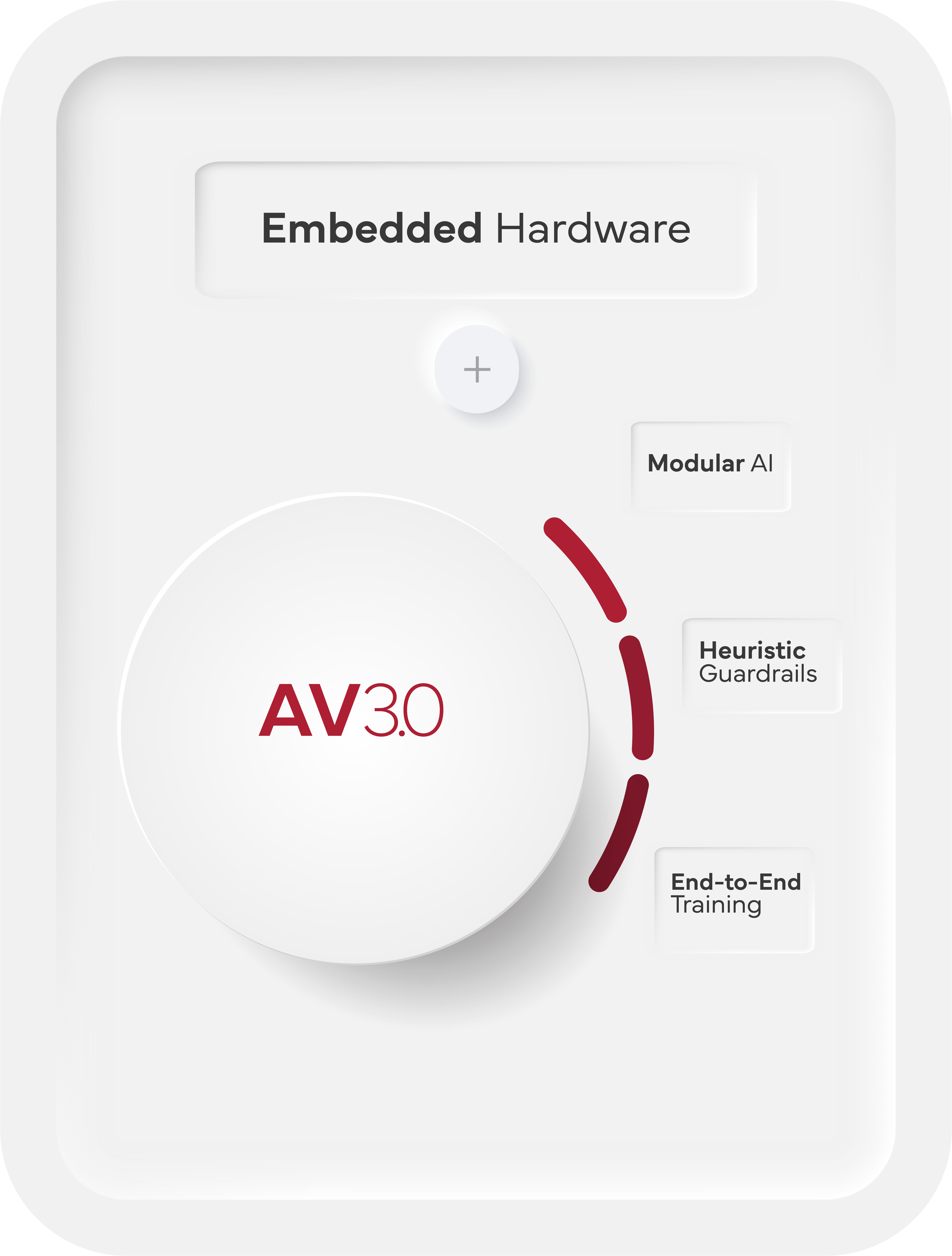

We refer to our AI software suite as Torc’s Virtual Driver: our advanced approach on seeing, thinking, and acting for self-driving trucks. Torc’s Virtual Driver combines cutting edge end-to-end learning and verifiable AI with algorithmic redundancy, allowing Torc to quickly evolve and scale to interpret the world around it, as well as adapt and absorb new sensor technologies and customer routes.

You Might Be Interested In: Daimler Truck’s Autonomous-Ready Fifth Generation Freightliner Cascadia Hits Texas Roads With Torc

Achieving Safe and Accurate Perception, Planning, and Prediction

To train and verify the models within the Virtual Driver, and make our technology as robust as possible, Torc uses novel generative AI approaches for our software testing. It assesses the Virtual Driver by driving billions of miles in every conceivable circumstance (more miles than a human would ever be able to drive in their lifetime) in simulation before it hits the road, and making changes as needed in real-time. AI isn’t just saving us time – it’s saving lives by helping us create situations most humans would never encounter, such as various weather conditions, unexpected pedestrian or vehicle behaviors, and many other edge cases to deeply test that the Torc Virtual Driver works correctly in all conditions and scenarios.

“Overnight, we can create a massive number of heavily optimized scenarios with parallel conditions that we can use for training very easily. This also allows us to scale the data we need much more easily for verification and validation of the software,” says Felix Heide, Head of AI at Torc. “It is possible to train software models and perform object detection without any training data on completely unseen, unannotated sequences of frames. We can use any real-world videos from a vehicle dash cam or test vehicle and use AI to match objects in an image frame, create our own settings, and finally derive a myriad of scenarios in a novel way to get away from the heavy reliance on limited training data sets. Training the systems to make decisions through reinforcement learning achieves optimal outcomes.”

Together, the modular AI powered Virtual Driver, taught and tested by next-level generative world simulation AI and further validated in the real-world, elevates Torc’s AI approach to the next level.

Torc’s technology unlocks high-performance verifiable AI, what we call AV 3.0, the highest performance and safety measures in the industry. With real world plus generative AI data loops working together, Torc’s AV 3.0 approach on our production embedded hardware enables fast and predictable product scaling for our fleet customers.

Partnerships Make It Happen

Importantly, our technology is built on best-in-class industry partnerships. Our Virtual Driver runs on the Flex Jupiter high-performance embedded compute platform, powered by NVIDIA DRIVE AGX™ technology. It is factory-integrated within the industry’s first and only autonomous-ready Class 8 truck chassis, the 5.0 Freightliner Cascadia developed by Daimler Truck, providing highest reliability and volume for our fleet customers.

Taken individually, it’s impressive. Together, it’s unequaled. We’re offering our customers unparalleled levels of redundancy and high reliability. And with the Freightliner Cascadia already owning nearly 60% of the U.S. Class 8 long-haul trucking market share today, this product and this partnership cannot be matched.

Torc has the best power, performance, and cost advantages for freight companies moving to adopt self-driving trucking. Our strong collaborations ensure autonomous trucks can be quickly produced at scale to meet manufacturing and market demands by our customers.

You Might Be Interested In: Torc Collaborates with Flex on Physical AI Platform for Autonomous Trucks, Accelerated by NVIDIA

Our AI-powered simulation

make us fast, flexible, and efficient.

AUTONOMY FORWARD

Torc’s differentiations are distinct and our customer engagements prove we’re on the right path to delivering the right self-driving product at the right time. We’re combining all the pieces in the right order:

- Our deep integration with Daimler Truck, building the autonomous-ready Freightliner chassis for safer, more reliable, day-to-day autonomous freight operations

- Cutting-edge AI – AV 3.0 – providing end-to-end self-driving capabilities that are safe, scalable, and adaptable for US road networks

- The embedded automotive-grade hardware needed to run Torc’s autonomous software, allowing for reliable real-time operation in harsh environments

But that’s not the end of the story. We’re not just working on the software and hardware. Our commercialization team is working closely with fleets today to understanding their needs tomorrow, their existing network infrastructure, and their pain points, so that we have the right application and tooling when the autonomous trucks are on the road.

The road to 2027 is paved with groundbreaking advancements, and with the support of AI technology, market and industry leaders, and the best team in the business, we’re driving toward a future where autonomous trucking transforms the way goods move across the world. Torc is driving the future of freight.

Our use of AI is governed internally by a cross-functional committee. The Generative AI Committee is dedicated to achieving Torc’s business objectives while adhering to the company’s commitment to Do the Right Thing. The Generative AI Committee’s mission is to establish a program to ensure AI systems used across Torc business functions conform with enterprise values, policy compliance, regulatory standards, and industry best practices.

- From engines to algorithms: Gen AI in automotive software development, January 2025, https://www.mckinsey.com/features/mckinsey-center-for-future-mobility/our-insights/from-engines-to-algorithms-gen-ai-in-automotive-software-development. AI tools have revealed a “productivity improvement of 44 percent when using gen AI with quality assurance measures, such as creating and automating tests to then enhance efficiency and code reliability.”