Strategic Location Taps into Regional Automotive and Tech Talent, Builds on Recent Dallas Forth-Worth Expansion

Blacksburg, VA – June 24, 2025 – Torc, a pioneer in commercializing self-driving class 8 trucks, today announced the establishment of a new engineering center in Ann Arbor, Michigan. As Torc continues its path toward commercialization in 2027, this strategic expansion will further accelerate the company’s productization efforts and tap into the region’s rich automotive and technology talent pool.

As part of its effort to open the Ann Arbor location, Torc worked closely with the Michigan Economic Development Corporation to secure incentives to support the expansion into Michigan, as Torc plans significant hiring in this region to grow its team and technical talent capabilities.

Torc’s Ann Arbor site will help drive critical product milestones. A diverse range of engineering roles will be based in the office, including expertise in machine learning, software, hardware, and systems engineering, alongside positions in product engineering, safety, and other key functions.

“This strategic location is a natural fit for Torc as we continue to advance our autonomous technology,” said Jamie Swaim, Chief People Officer at Torc. “Ann Arbor’s proximity to the Detroit automotive industry and a wealth of high-tech talent, combined with the exceptional concentration of high-caliber universities and colleges, makes it an ideal environment for our growth and productization strategy. This new center will complement the strong engineering talent we already have across the nation.”

The new office, located in northeast Ann Arbor, will encompass approximately 32,000 square feet and will feature multiple collaboration spaces and hardware in the loop labs.

“We are pleased to support the continued growth and expansion of Torc, whose project is a testament to the strength of our state’s mobility industry and Michiganders’ superior skills,” said Quentin L. Messer, Jr., CEO of the Michigan Economic Development Corporation and chair of the Michigan Strategic Fund. “My congratulations and gratitude to Torc; we are honored to earn this investment. We look forward to celebrating your future success and that of the People, Places, and Projects who will benefit from your presence in the great state of Michigan.”

Torc’s decision to establish a presence in Ann Arbor underscores its commitment to fostering innovation and teamwork through strategic talent acquisition and collaboration within key technology and automotive ecosystems. For more information on Torc, please visit www.torc.ai.

About Torc

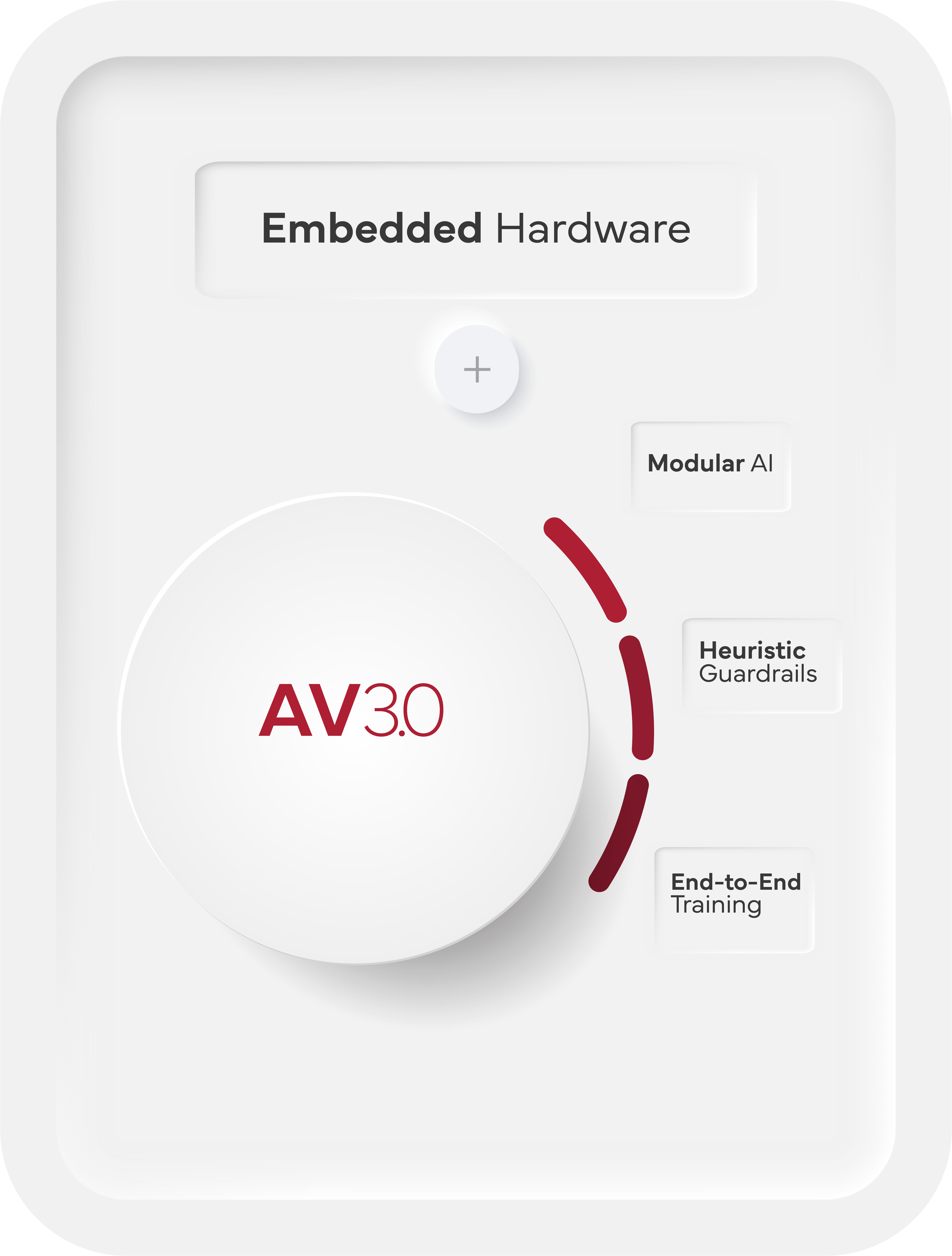

Torc, headquartered in Blacksburg, Virginia, is an independent subsidiary of Daimler Truck AG, a global leader and pioneer in trucking. Founded in 2005 at the birth of the self-driving vehicle revolution, Torc has over 20 years of experience in pioneering safety-critical, self-driving applications. Torc offers a complete self-driving vehicle software and integration solution and is currently focusing on commercializing autonomous trucks for long-haul applications in the U.S. In addition to its Blacksburg headquarters and engineering offices in Austin, Texas, and Montreal, Canada, Torc has a fleet operations facility in the Dallas-Fort Worth area in Texas, to support the company’s productization and commercialization efforts, as well as a presence in Ann Arbor, MI, to take advantage of the autonomous and automotive talent base in that region. Torc’s purpose is driving the future of freight with autonomous technology. As the world’s leading autonomous trucking solution, we empower exceptional employees, deliver a focused, hub-to-hub autonomous truck product, and provide our customers with the safest, most reliable, and cost-efficient solution to the market.