Becoming an Autonomous Vehicle Engineer – Part 1: Beginning the Journey

Part 1 of 3 in Torc’s series about how to prepare for a career creating autonomous vehicles.

Imagine creating a machine that can perform all the complex decisions and behaviors that a human can while operating a motor vehicle.

A human driver on the highway at 70 mph must navigate safely to their destination all while tracking and adapting to multiple lanes of traffic. The driver has to adjust for the speed of surrounding vehicles, anticipate the actions of other drivers, zipper into traffic while entering and exiting the highway, and pay attention for variables like lane closures and construction – all while covering the length of a football field every three seconds.

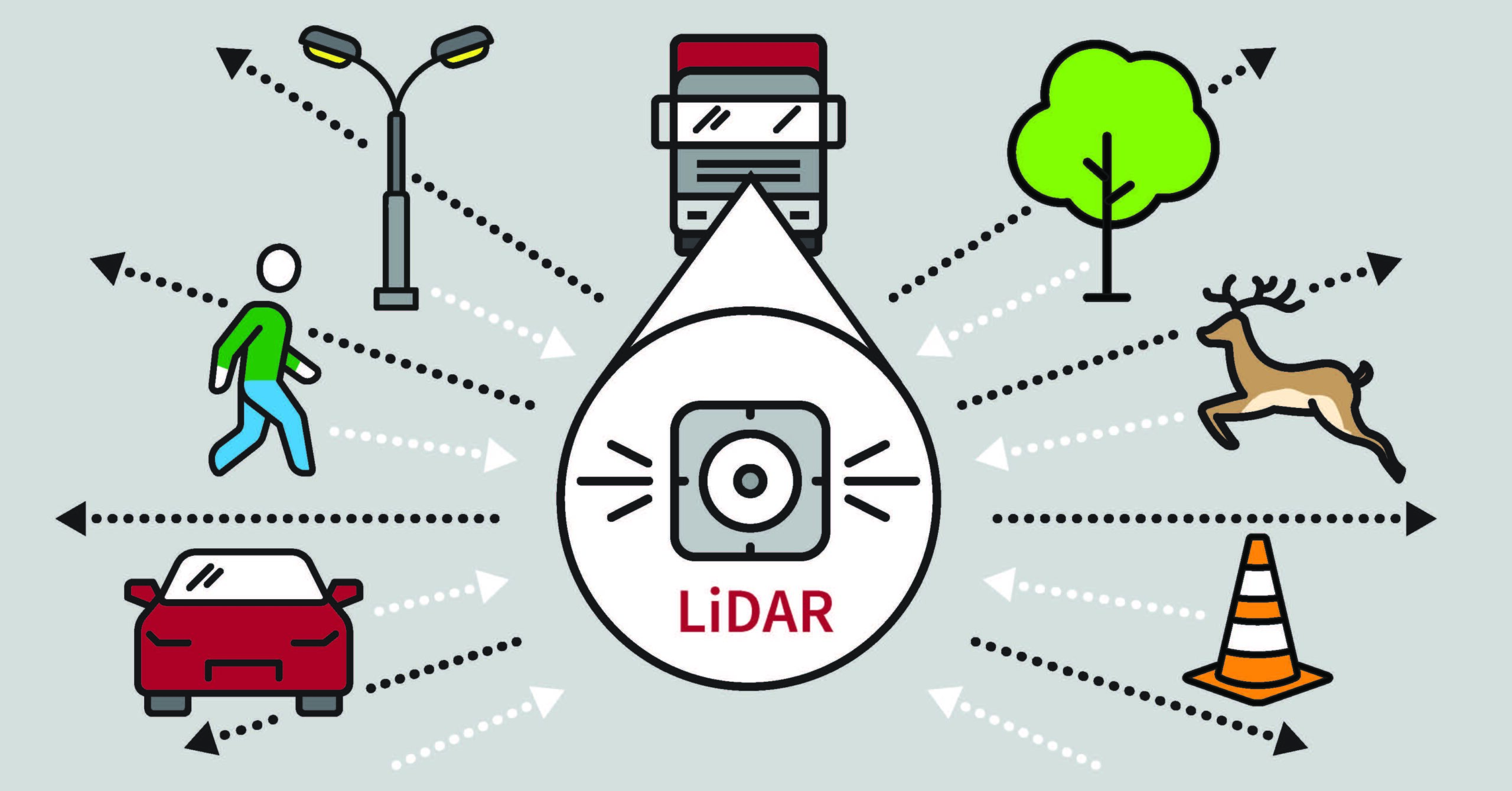

Creating a system that is capable of all these capabilities is a complex task – one that requires a team of dedicated individuals to create the eyes, brain, and behaviors the system needs to handle all the unexpected corner cases on a road.

At Torc, we believe the challenge is worth taking on. AVs will allow more freedom and accessibility for travel, a more efficient way to move goods, and a much safer roadway.

Autonomous technology is developing so quickly that it’s difficult to create a roadmap, leaving a lot of aspiring engineers to wonder, “how do I become a self-driving vehicle engineer?”

In this three-part blog series, we’ll share experiences from current Torc engineers as well as general knowledge we’ve gained from 14 years in the autonomous vehicle business.

Develop core engineering knowledge and skills

We look for engineers who have built their knowledge around a solid foundation of engineering and software skills. What do we mean by core skills?

- Critical thinking skills that will allow you to approach a problem from multiple angles

- Core knowledge of how components interact so that you can anticipate how your role affects the entire system

- An understanding of the best practices for software development

- The ability to work with a team to bring a project from conception to execution

Many engineers who started at Torc have evolved their roles as the technology and projects have evolved. Their core skills allowed them to adapt to the ever-changing environment.

Build experience with academic projects and team competitions

In 2005, a small group of Virginia Tech engineering students entered their autonomous vehicles into a series of competitions and won. Inspired, they decided to form a company called TORC. From there, they partnered with more VT engineering students and entered the DARPA Challenges – now a legendary set of competitions that launched many of the AV companies today. Twelve years after the challenges, Torc is working with top companies in the public transportation, defense, and trucking industries to create Level 4 autonomous solutions that we believe will change the world.

Joining a team of dedicated people toward a common goal can jump-start your career in AV engineering.

- Not in college yet? Try looking for FIRST Robotics Competitions and school projects in STEM. Seek out mentors and teachers in the field.

- If you’re in college, join robotics projects and competitions in areas of your interest to build experience and progress with a team. Someday, these may be your future colleagues.

- If you’re pursuing a secondary degree, consider a master’s project that pushes you to learn something specialized related to the field of autonomy.

Torc’s story exemplifies the power of joining a team to work toward solutions that have never been created before. We asked Torc engineers to talk about their journey working on autonomous systems and give advice to those looking to enter the world of AV engineering.

Scott Schlacter, Embedded and Controls Team Lead

The two major academic activities that shaped my desired to build robots was my participation in CUAir (a student-run competition team that builds unmanned aerial vehicles and competes at an annual AUVSI competition) and my work for the Autonomous Systems Laboratory during my senior year and graduate school.

My advice for someone who wants to work on self-driving vehicles would be to find as many people to learn from as you can and listen to them. No one person is going to have all the right answers, but if you can effectively combine as much knowledge as possible, you’ll get a leg up.

Parissa, Director of Operations

I started my career as an optical engineer, which was my undergrad degree. Then, I decided to do my master’s degree in Systems Engineering because I like seeing how everything comes together in the bigger picture. I was at my last job for about eight years, so I went from being an optical engineer to a project engineer, which is more of a systems engineering role.

When I came into Torc as a project manager, I was able to leverage that background of understanding the technical development and the big picture and planning side of things. Over the years, I have gone from managing the project managers to taking on a bigger role as Director of Operations. My role is leveraging a lot of my engineering background. I think understanding how the R&D engineering process works and how engineers would go about developing the system has helped me to see how all the different pieces work and put them all together.

David Anderson, Principal Mechnical Engineer

My first project in unmanned systems was in a CAD class as a junior at Virginia Tech. Our group project was to design the drive-by-wire steering system for Cliff, Virginia Tech’s entry vehicle for the 2004 DARPA Grand Challenge.

I continued working on the DARPA Challenges for my senior keystone design project and throughout my master’s work. I’m proud to say that everything visible on VT’s Urban Challenge vehicle “Odin” was my responsibility, from the paint scheme and sponsor logos, to all sensor mounts and interior bracketry.

Focused knowledge in your specific area of development (whether it be software, mechanical, wiring etc.) is critical to being successful. However, the ability to understand how the entire system works together is even more important. What does this system need to do to make it successful?In what situations does that sensor perform well, and in what situations is it not optimal?Then, how is that data communicated to the computer?

You will benefit from being able to see the “30,000-foot view” as well as drilling down to the specifics. This allows for the whole system to integrate with much more fluidity.

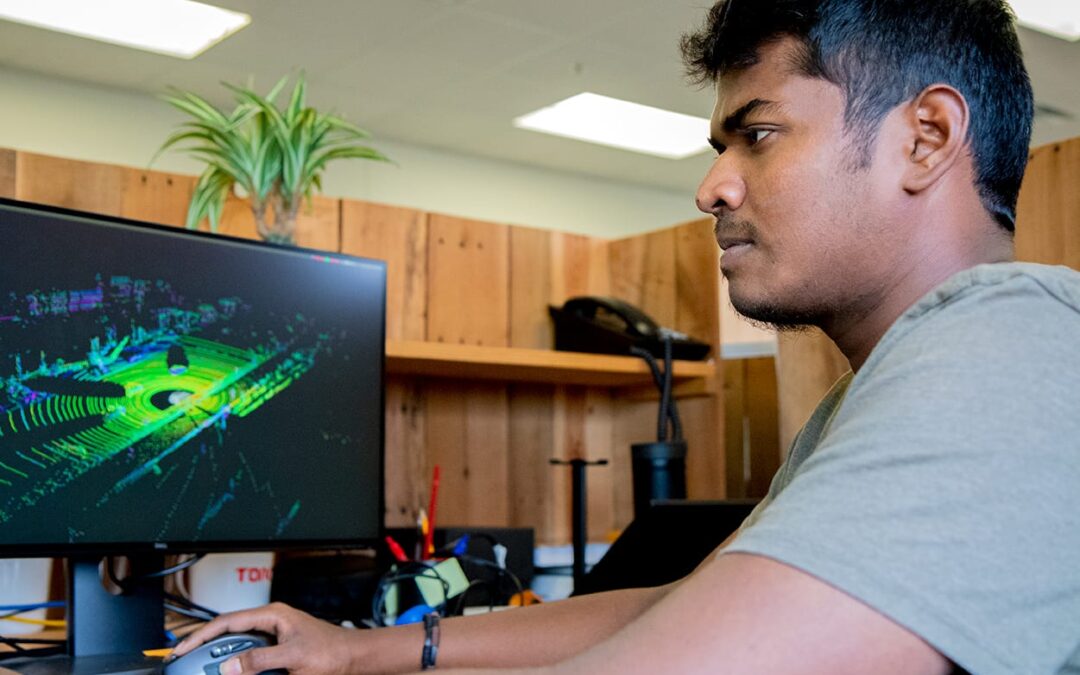

Rohit Salem, Software Engineer in Perception

I received my master’s degree in Robotics at Worcester Polytechnic Institute (WPI). Robotics is one of the most diverse fields one can find in engineering. If you are unsure of what specialization you’d like to work on (like I was), or which field of robotics you want to choose – because all of them are pretty darn cool – you have to try out a few different things.

I decided to explore one course for each specialization in the program. After doing those projects, I felt I was more inclined towards perception. Taking more courses and doing more projects in perception helped me land in an internship where I worked on deep-learning and perception. I’m continuing to work in the same field at Torc.

Next Steps – Languages and Skills

At Torc, we develop our own end-to-end software stack and integration solutions for every project we take on. This requires a diverse team with different skill sets and backgrounds to create the next level of transportation.

In part two of our blog series, we detail the specific teams that bring our autonomous projects to life and engineers explain which coding languages and skills will help you be successful as an autonomous vehicle engineer.

Looking for jobs in autonomous vehicles? You came to the right place. Torc is one of the most experienced autonomous software companies and we are growing our team of dedicated engineers. See our careers page for more and check out part two!