Scaling Physical AI for Autonomous Trucking Today: Torc’s First-to-Production Embedded Hardware

In the first article about Torc’s AV 3.0 technology, we covered the different system components of AV 3.0: the virtual driver software, and the advanced data loop and generative AI simulation infrastructure to train and test it. AV 3.0 is the robust technology needed to safely and efficiently create an autonomous trucking product.

However, AV 3.0 is more than just world class autonomous software. We’re running this physical AI product on high-volume embedded compute in production-ready vehicles today.

We’re the first in the industry to deploy our system on a production-intent platform — Daimler Truck’s autonomous-ready Freightliner Cascadia. By running our AV 3.0 system on this autonomy-specific redundant chassis, Torc is setting the industry standard in the autonomous trucking space and leading the way to commercially scalable and viable freight solutions.

The Embedded Hardware Engine of AV 3.0

Freight movement presents unique challenges that require unique trucking solutions. Systems like long range perception, long-distance-actor prediction, and extended behavior planning are non-negotiable. Add in that the physical compute platform needs to hold up to running millions of miles in harsh long-haul trucking environments.

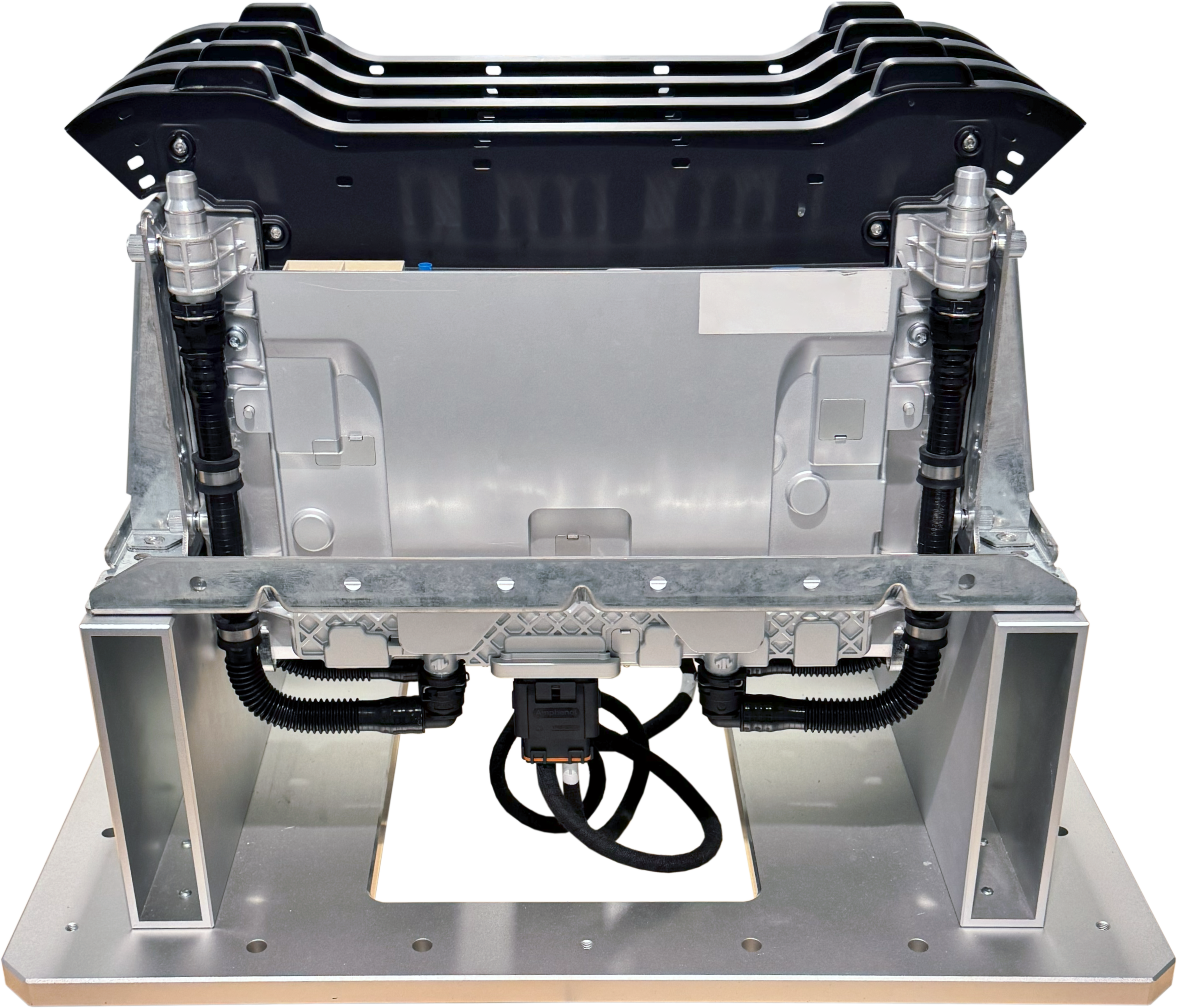

We worked with Flex to optimize the performance, cost, power, and reliability of our embedded compute platform to meet the stringent requirements needed for running Torc’s AV 3.0 virtual driver. This is no commercial server rack setup packed full of GPUs in the cab.

It’s optimized to drive the future of autonomous freight and nothing else.

Our multi-chip adaptable architecture leverages:

- Flex’s Jupiter platform

- NVIDIA DRIVE AGX

- NVIDIA DRIVE Orin system-on-a-chip

- NVIDIA DriveOS operating system

Rishi Dhall, Vice President of Automotive at NVIDIA (when the partnership was announced in March 2025 ) said, “NVIDIA DRIVE AGX has been industry-proven in full production for automotive real-time applications at the edge. It delivers the high compute performance, low latency, and multi-sensor connectivity needed for Torc’s sophisticated autonomous trucking software, delivering robust perception, prediction, and planning for safe and reliable operation. Torc is on a clear path to scalable production for its commercial launch in 2027.”

Mike Thoeny, President of automotive at Flex, was also quoted at the time: “Our collaboration with Torc, Daimler Truck, and NVIDIA illustrates how Flex partners across the full ecosystem to enable mobility companies to launch next-generation technology with greater resilience and speed. We appreciate the trust Torc and Daimler Truck have placed in Flex through leveraging our Jupiter compute platform and advanced manufacturing capabilities to deliver autonomous long-haul trucking at scale.”

Torc’s work to achieve AV 3.0 has been intense, and the timeframe impossibly short, but this necessary step was anticipated years ago and well executed by the hundreds of dedicated Torc’rs that made it possible. Torc has staked our claim amongst the competition as the first autonomous freight company to fully shift to a production embedded platform.

Advanced Driver-Assistance System (ADAS) Applications.

Image courtesy of Flex.

Jupiter-T unit for Torc. Level 4 ADAS. Image courtesy of Flex

“The incredibly intensive, time-consuming, and technically challenging effort that it took to take the virtual driver software that runs on ‘unlimited’ datacenter server racks and make it work on the highly reliable Flex embedded compute platform, all while not sacrificing performance, is a technological marvel.”

– Stephan Vargas, Torc Technology Vice President (Compute Foundation)

Pieces of the Whole

In 2019, Torc made history by partnering with Daimler Truck, creating the first OEM relationship in the business. Torc’s leaders knew this partnership was the only path to delivering a safe and scalable product on time. Both companies knew the Cascadia Freightliner would be the top choice to house the industry’s best-in-class autonomous truck – and it’s all been realized.

Follow along as we map out what happened over the last year and why it’s important now.

October 2024: Torc Robotics Performs Successful Fully Autonomous Product Validation

In October 2024, the driverless production-intent truck, redundant components, AD Kit, and the first release of the production-intent virtual driver took to the road on a closed multi-lane test track. Clocking in at over five hours in highway settings, the test was conducted at full operating speeds of up to 65 mph to optimize fuel efficiency and emulate commercial timings and conditions for future long-haul routes. The test signaled a sea-change for Torc, shifting cycles from development to productization. This occasion was no demonstration. It was the proof point for years of work. The fully robotic from hub-to-surface-to-ramp-to-highway and back production intent hardware and software were successfully on the road.

March 2025: Torc Collaborates with Flex on Physical AI Platform for Autonomous Trucks, Accelerated by NVIDIA

In March 2025, we attended GTC in San Jose, where we announced our collaboration with NVIDIA and Flex.

April 2025: Daimler Truck’s Autonomous-Ready Fifth Generation Freightliner Cascadia Hits Texas Roads With Torc

To enable SAE Level 4 autonomous driving, the company has purposefully designed and built redundancy into the Freightliner Cascadia platform for safety-critical systems for safe, driverless operations. With over 1,500 engineering requirements, all translated into features, and a second set of electronically controlled systems like an integrated power network, the autonomous-ready Cascadia sets an industry standard for autonomous systems integration. – Daimler Truck press release April 2025

To enable SAE Level 4 autonomous driving, the company has purposefully designed and built redundancy into the Freightliner Cascadia platform for safety-critical systems for safe, driverless operations. With over 1,500 engineering requirements, all translated into features, and a second set of electronically controlled systems like an integrated power network, the autonomous-ready Cascadia sets an industry standard for autonomous systems integration. – Daimler Truck press release April 2025

The autonomous-ready Freightliner Cascadia announced by Daimler Truck in April 2025 includes all essential compute stack components and sensors installed on the production line; a step that allows seamless integrate of the virtual driver software without retrofitting the platform.

Importantly, the vehicle and platform had already been proven and validated at our driverless product acceptance test in October 2024, six months prior.

May 2025: Torc Commercial Center Operations Commence

After 20 years in the robotics business, and six years of software research and development, Torc officially opened the company’s first commercial hub in May 2025, getting our trucks officially on the I-35 corridor. Our fleet has moved from our testing grounds in Albuquerque to focus on the Laredo to Fort Worth route, a crucial freight lane for many large freight customers. We’re already working in concert with them as we continue to look for more opportunities for the latter half of 2026.

After 20 years in the robotics business, and six years of software research and development, Torc officially opened the company’s first commercial hub in May 2025, getting our trucks officially on the I-35 corridor. Our fleet has moved from our testing grounds in Albuquerque to focus on the Laredo to Fort Worth route, a crucial freight lane for many large freight customers. We’re already working in concert with them as we continue to look for more opportunities for the latter half of 2026.

August 2025: Torc Technology Center Opens

There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

September 2025: AV 3.0 Technology Debuts

There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

“We’ve never been focused on chasing timelines, or on demonstrations or headlines. We’ve just been focused on a safe and scalable product from the beginning and just doing what’s right for the industry and our partners.”

– Peter Vaughn Schmidt, CEO

Onward To 2027

We’re leading the wave of physical AI applications with our simulation environment, our computation and sensing hardware are defining the industry, and future customers are getting ride-alongs inside our production-intent trucks in Texas today. We’re set up to immediately scale and deliver on customer demand.

So, now what? What will we be doing until market entry?

Over the coming months, we’ll be sharing more about hub operations and the development of workflows and job creation, customer autonomous fleet onboarding transition plans, our commitment to safety and the release of our safety case, and more cutting-edge simulations and visualizations from our technology and trucks. We have time to solve a multitude of other necessary autonomous trucking puzzles, truly making Torc the industry leader, driving the future of freight.

Follow us on our social channels to keep up to date with all our announcements and upcoming events.

“There are two kinds of autonomous trucks on the road today, at the end of 2025. There are demonstration trucks – and there are Torc trucks.”

– Andrew Culhane, Chief Commercial Officer