Proven, Not Promised: Earning Our Place on the Road

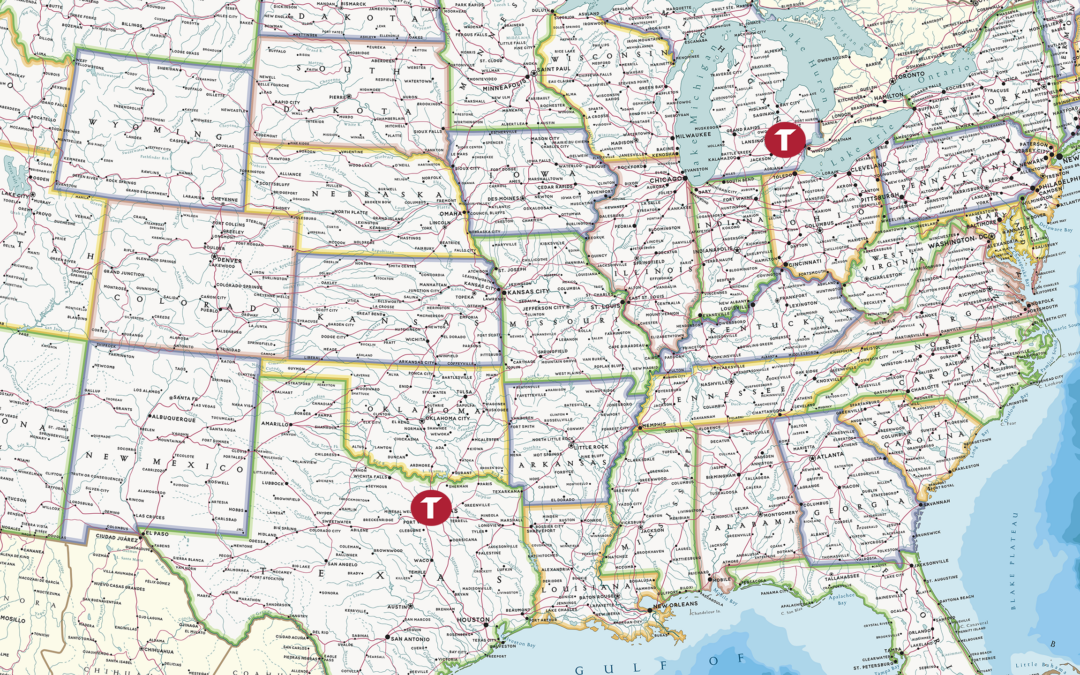

At Torc, safety isn’t just a priority; it’s the foundation that supports every aspect of how we develop, deploy, and operate our autonomous trucking technology. As we work to transform commercial freight transportation, we’ve built an approach that establishes trust with regulators, our customers, and the public, that Torc’s autonomous solutions are safe to deploy and in the communities we operate in.

Torc’s Chief Safety Officer, Steve Kenner, and his team have developed a safety framework organized around three pillars that guide our safety philosophy. Individually, they keep different parts of our whole team accountable to specific segments, such as the engineering of our trucks, how they’re operated, and how safety is fostered within Torc. Together, they ensure we’re not just building a safe autonomous truck but operating it responsibly.

Build it Safe

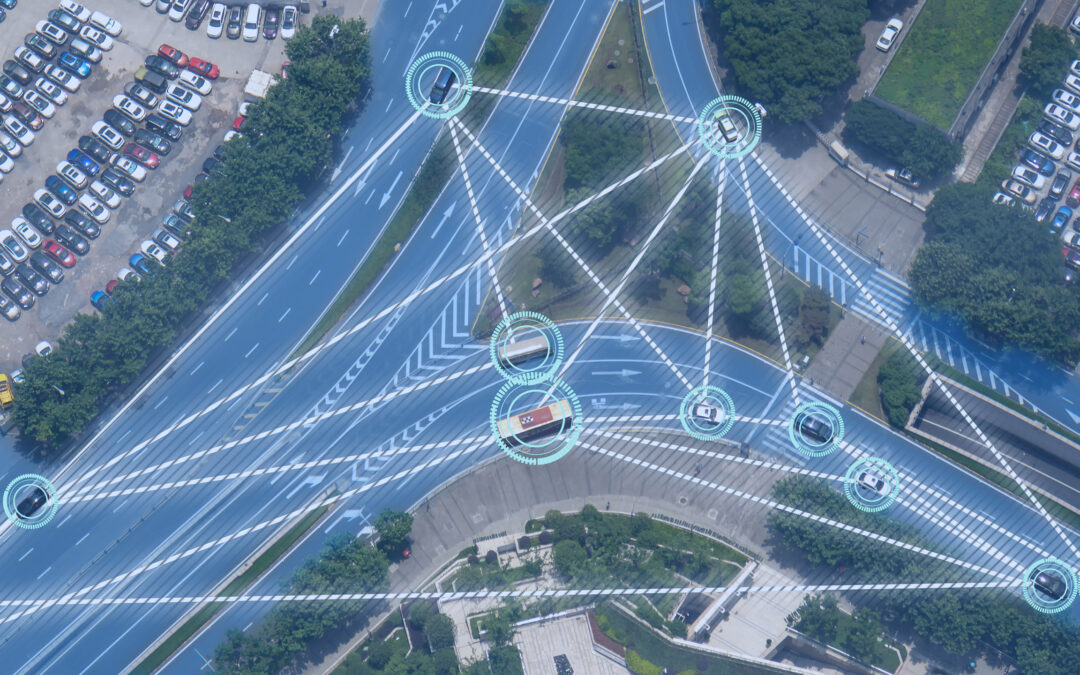

The foundation of our safety approach starts with the truck itself. We’ve engineered multiple layers of redundancy into our hardware as well as our autonomous driving systems, embedded on the industry-leading Freightliner Cascadia platform, to ensure safe operation even when individual components fail.

- Redundancy at Every Level

Our redundancy approach encompasses all critical systems. Our safety philosophy spans all aspects of our technology, from our system architecture to our hardware and software design, allowing us to be resilient to failures. This is accomplished through redundancies in our safety-critical systems, such as braking and steering.

For instance, if an individual sensor fails, we can achieve an MRC (minimal risk condition) by pulling off the road at a safe location. The redundancies we’ve built in allow us to continue operating safely.

- Intelligent Fault Management

Torc has developed a sophisticated fault-management system that detects faults, including safety-relevant faults, and matches them to appropriate responses. Our priority hierarchy is clear: first and foremost, our trucks must maintain safe operations and refrain from creating a hazard for other road users. If we can’t reach our destination, we focus on degraded operation that gets us to a safe location, rather than just pulling to the roadside. Think truck stop or exit ramp, not highway shoulder. However, in safety-critical situations, our autonomous truck will pull over to the side of the road as soon as it is safe to do so.

- Addressing Edge Cases

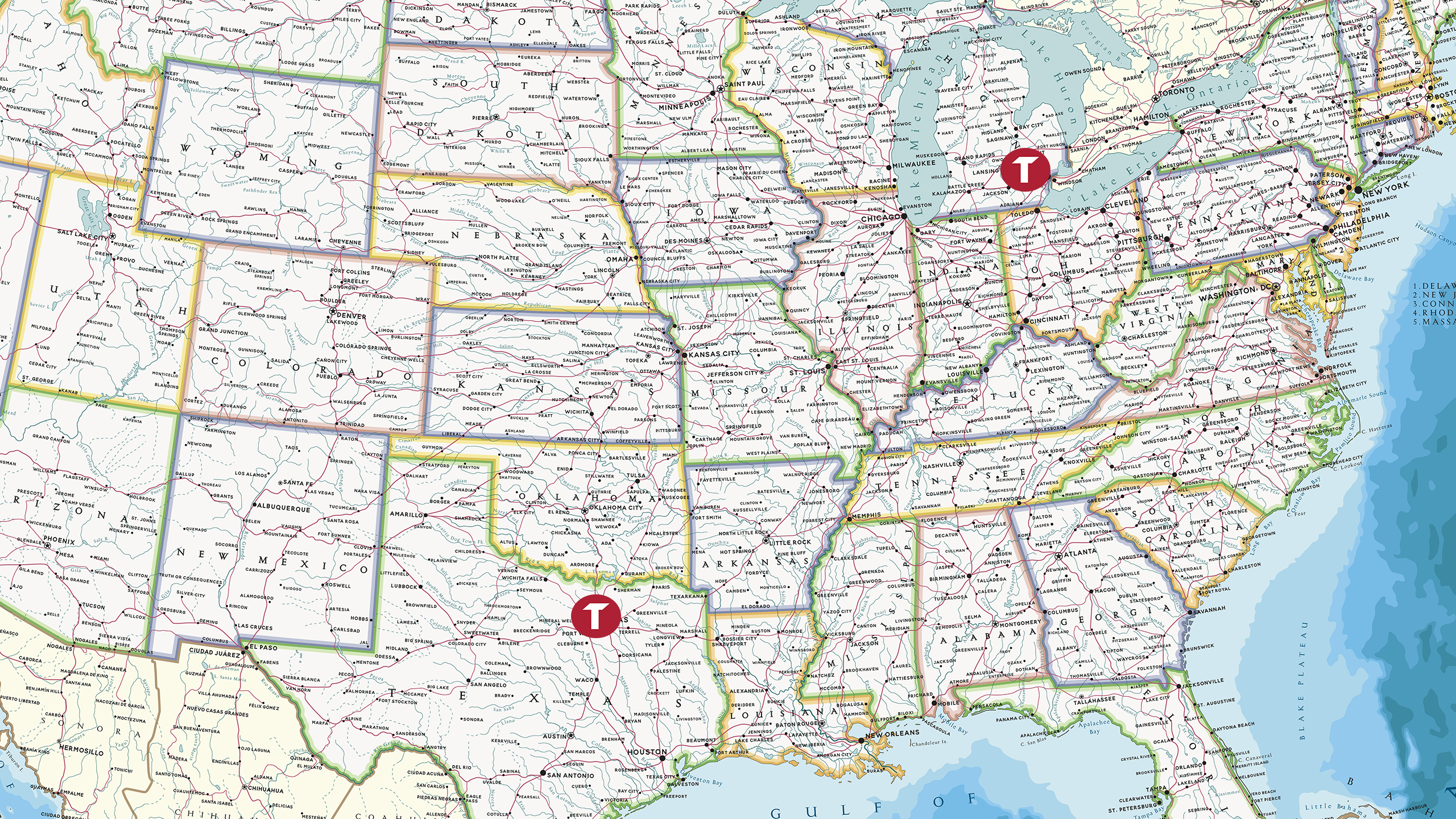

Edge cases (problems or situations that occur at the extreme limits of a system’s operating parameters) are inevitable in the real world. Whether it’s a billboard featuring a giant stop sign that could be misidentified by sensors, or a pickup truck loaded with Christmas trees, our autonomous driving system needs to handle a multitude of scenarios not previously encountered. Torc is tackling this challenge through a collaboration with Stanford University, where we’ve partnered to make the future of freight safer for all. By sharing our data and perception information with our partners, we’re able to compare datasets and identify differences between them. For instance, let’s say our simulation training data includes lots of pickups loaded with wooden planks, but we don’t have any of those same “real world” vehicles in our on-road perception data. These kinds of insights allow us to identify areas where we should develop a more complete perception dataset.

We also leverage publicly available crash databases from the National Highway Traffic Safety Administration and state agencies to analyze crashes on our planned routes (as well as roads outside of our routes) but within our ODD or operational design domain, which the set of specific conditions and locations under which an automated system can/is allowed to operate. This allows us to replay and recreate these scenes during software testing, using AI generated scenarios in our simulation environment. We can test and train the software’s responses to both real-world crashes and even more challenging simulated situations.

- The Role of Simulation and Testing

Let’s dive deeper into Torc’s simulation environment and our testing and training. Torc firmly believes that you cannot real-world-road-test our way to safety. Even millions of miles on the road wouldn’t be enough to encounter all potential edge cases. Therefore, we use a balanced combination of (1) real-world data and (2) generated AI simulated scenarios to test our software, and then (3) retraining the system as a whole. We use safety metrics, such as hard breaking, hard swerves, and total time to collision that allow us to measure performance in both environments and establish parity between simulation and on-road results.

Our comprehensive simulation libraries provide scalable, cost-effective testing capabilities, but we still need sufficient on-road miles to validate our software against real-world performance.

Operate it Safe

Technology is only part of the safety equation. With autonomous trucking, Torc is improving how freight operations work and realize efficiencies, prompting new approaches to maintenance, inspection, and human oversight:

- Evolving Operational Standards. Our autonomous technology requires updated maintenance and inspection protocols compared to traditional trucking operations, such as sensor calibration and increased frequency. We’re developing the training programs and procedures that will equip fleet operators and technicians with the skills they need to work with autonomous vehicles.

- Human Oversight Philosophy. We’re establishing clear guidelines as to when remote assistance should assist a vehicle when it encounters situations that may require human oversight. This balance ensures that human judgment enhances rather than undermines our autonomous capabilities.

- Consistent Standards Everywhere. Safety standards must be maintained across different routes, terminals, and regulatory environments. We’re building systems that adapt to varying environments while maintaining our core safety principles.

Trust It To Be Safe

We recognize that the biggest challenge we face now isn’t necessarily technical; Torc has already overcome that. It’s earning public trust. We’re committed to establishing and maintaining safety from our fellow drivers, regulators, partners, and our community at large.

- Transparency and Engagement

As Torc CSO Steve Kenner puts it, “We’re all in charge of public safety.” We maintain transparency with regulators and elected officials who are responsible for public safety, engaging with stakeholders at city, county, state, and federal levels. We want people to understand what we’re doing, how we’re doing it, and when we’re doing it. This includes comprehensive first responder interaction plans and training programs, like these, ensuring that emergency personnel understand how to interact safely with our vehicles.

- Independent Validation

We understand that industry self-assessment isn’t enough. That’s why we’re working with third parties like Stanford’s Center for AI Safety and Edge Case Research; we’re actively seeking out neutral third-party studies and evaluations of our work to ensure that we’ve created a complete picture of our safety case.

- Industry Collaboration

Torc believes that rising tides lift all boats, so, while we compete on many aspects of our business, we should always collaborate on safety. We participate in industry consortiums and safety organizations, such as the Automated Vehicle Safety Consortium, sharing knowledge that advances autonomous vehicle safety across the entire sector, while respecting antitrust and intellectual property requirements.

How It All Comes Together: Governance and Risk Management

These three pillars of Torc’s safety approach don’t operate in isolation; they’re connected through a comprehensive governance structure centered on risk management. We’ve established a flexible safety governance framework where safety decisions can be promptly reviewed by a cross-functional team of experts. These committees report up to the Torc safety board, which CSO Steve Kenner leads.

Safety risk management is pervasive throughout our approach. We systematically identify safety hazards and develop mitigation strategies across all our operations, whether we’re selecting hardware, planning operations, or making any other business decisions. Our safety risk management framework provides the structure for how we assess and evaluate these safety risks.

Earning Our Place on the Road

As autonomous trucking technology continues to mature and regulatory frameworks evolve, our three-pillar safety philosophy provides a comprehensive approach to the complex challenges of deploying self-driving vehicles at scale. We’re not just working to put autonomous trucks on the highway – we’re working to earn their place there through demonstrated safety, reliability, and responsible operation.

The transformation of commercial transportation will succeed only if we can prove that autonomous vehicles operate safely alongside human drivers while delivering the efficiency and economic benefits they promise. Our systematic approach to safety, governance, and public engagement is designed to make that vision a reality.

At Torc, safety isn’t just what we do; it’s who we are. Every decision we make, every system we build, and every mile we drive is guided by our commitment to operating safely and earning the trust of everyone who shares the road with us.