TEL AVIV, Israel: PORTLAND, Ore. and BLACKSBURG, Va. – December 2, 2025 – Innoviz Technologies Ltd. (NASDAQ: INVZ) (the “Company” or “Innoviz”), a leading Tier-1 direct supplier of high-performance, automotive-grade LiDAR sensor platforms and complementary software stack, announced today that Daimler Truck, one of the world’s leading commercial vehicle manufacturers and Torc Robotics, a subsidiary of Daimler Truck, have selected Innoviz as its Short-Range LiDAR supplier for series production SAE Level 4 autonomous Class 8 semi-trucks.

This announcement follows Innoviz’s previous disclosure that a major commercial vehicle OEM had selected the Company for future series production of Level 4 autonomous trucks, now revealed to be Daimler Truck. Innoviz will supply its InnovizTwo Short-Range LiDAR sensors to support Daimler Truck and Torc Robotics’ autonomous commercial vehicle program. As part of a joint development effort, the companies will collaborate to advance the sensors for commercial trucking applications.

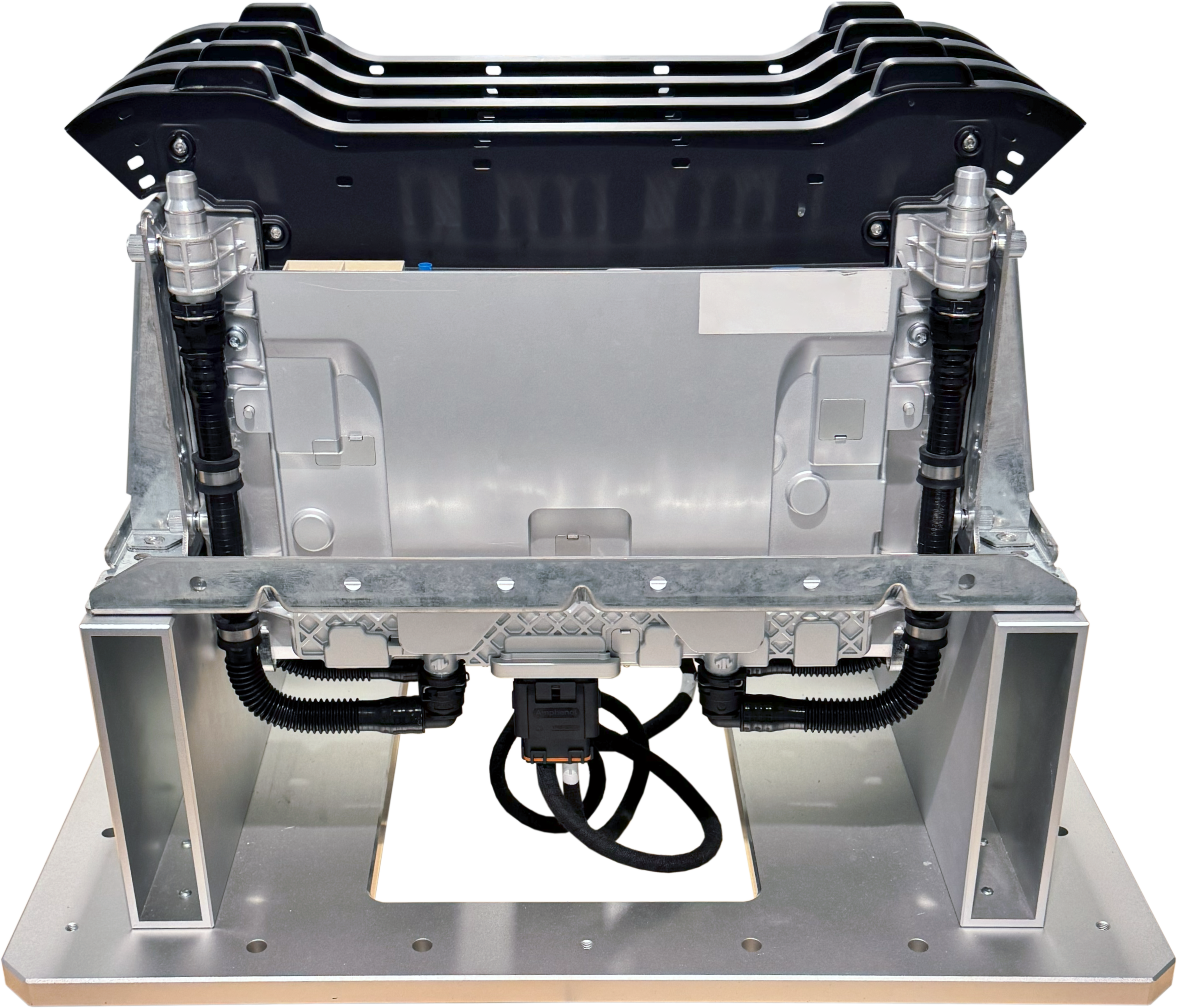

Daimler Truck and Torc Robotics plan to integrate Innoviz’s LiDAR technology into the autonomous Freightliner Cascadia in combination with Torc’s virtual driver as one of several key components enabling Level 4 autonomous trucking.The partnership positions Innoviz’s technology as a critical component in Daimler Truck’s strategy to bring autonomous trucks to market, with deployment planned across highway and regional routes in North America to help fleet operators improve operational efficiency, and enhance road safety.

“This partnership with Daimler Truck and Torc represents a significant validation of our technology and our position in the autonomous trucking market,” said Omer Keilaf, CEO and Founder of Innoviz. “The trucking industry demands LiDAR sensors that can perform reliably in the most challenging conditions while delivering the precision and range needed for safe autonomous operation. Our InnovizTwo sensors have demonstrated compliance with these stringent requirements, and we’re excited to support Daimler Truck and Torc in bringing this transformative technology to market.”

“Selecting the right LiDAR partner is fundamental to our autonomous trucking strategy,” said Rakesh Aneja, Head of Corporate Development at Daimler Truck North America. “Innoviz’s proven track record in automotive-grade LiDAR sensors makes them an ideal partner as we advance toward series production. This collaboration brings us closer to delivering autonomous trucks that will reshape the logistics industry.”

Mike Avitabile, Head of Engineering at Torc, adds: “Integrating Innoviz’s technology into our self-driving vehicle software solution enhances our system’s ability to detect, classify, and track objects in real time across diverse road and weather conditions. Innoviz’s sensors deliver the consistency and durability required for commercial operation, while supporting the redundancy needed for safe Level 4 autonomy.”

Daimler Truck and Torc rely on a combination of three complementary sensor technologies – state-of-the-art LiDAR, radar, and camera systems – to precisely detect the vehicle’s surroundings under all conditions. This multi-layered approach enhances road safety both on highways and in challenging maneuvers such as turning at intersections or navigating ramps. LiDAR technology uses laser pulses to generate high-resolution 3D maps of the environment. For maximum safety, autonomous trucks require both long-range LiDAR systems to identify objects far ahead and short-range sensors to capture detailed close-proximity data in complex driving situations. While Daimler Truck and Torc have already selected their supplier for long-range LiDAR, Innoviz has now been chosen as the partner for short-range LiDAR.

About Daimler Truck

Daimler Truck Holding AG (“Daimler Truck”) is one of the world’s largest commercial vehicle manufacturers, with over 40 main locations and more than 100,000 employees globally. Daimler Truck North America LLC (DTNA), a subsidiary of Daimler Truck and headquartered in Portland, Oregon, is the largest manufacturer of heavy-duty trucks in North America and a leading provider of innovative products, services, and technologies for the commercial transportation industry. DTNA designs, engineers, manufactures, and markets medium- and heavy-duty trucks, school buses, vehicle chassis, and related technologies and components under the Freightliner, Western Star, Thomas Built Buses, Freightliner Custom Chassis Corp, and Detroit brands. DTNA is dedicated to delivering exceptional value and support to its customers—helping them keep the world moving. For more information, visit northamerica.daimlertruck.com or daimlertruck.com.

About Torc

Torc, headquartered in Blacksburg, Virginia, is an independent subsidiary of Daimler Truck AG, a global leader and pioneer in trucking. Founded in 2005 at the birth of the self-driving vehicle revolution, Torc has over 20 years of experience in pioneering safety-critical, self-driving applications. Torc offers a complete self-driving vehicle software and integration solution and is currently focusing on commercializing autonomous trucks for long-haul applications in the U.S. Torc has offices in Montreal, Ann Arbor, Blacksburg, and the Dallas–Fort Worth (DFW) area. Headquartered in Blacksburg, Virginia, Torc also operates an engineering office in Montreal, a fleet operations facility in DFW to support productization and commercialization efforts, and a facility in Ann Arbor to leverage the region’s strong autonomous and automotive talent base. Torc’s purpose is driving the future of freight with autonomous technology. As the world’s leading autonomous trucking solution, we empower exceptional employees, deliver a focused, hub-to-hub autonomous truck product, and provide our customers with the safest, most reliable, and cost-efficient solution to the market.

About Innoviz

Innoviz is a global leader in LiDAR technology, serving as a Tier-1 supplier to the world’s leading automotive manufacturers and working towards a future with safe autonomous vehicles on the world’s roads. Innoviz’s LiDAR and perception software “see” better than a human driver and reduce the possibility of error, meeting the automotive industry’s strictest expectations for performance and safety. Operating across the U.S., Europe, and Asia, Innoviz has been selected by internationally recognized premium car brands for use in consumer vehicles as well as by other commercial and industrial leaders for a wide range of use cases. For more information, visit innoviz.tech.

Join the discussion: Facebook, LinkedIn, YouTube

Media Contact

Media@innoviz-tech.com

Investor Contact

Investors@innoviz-tech.com

Forward Looking Statements

This announcement contains certain forward-looking statements within the meaning of the federal securities laws, including statements regarding the services offered by Innoviz, the anticipated technological capability of Innoviz’s products, the markets in which Innoviz operates, Innoviz’s projected future operational and financial results. These forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties.

Many factors could cause actual future events, and in the case of our forward-looking revenues, actual orders or actual payments, to differ materially from the forward-looking statements in this announcement including but not limited to, the ability to implement business plans, forecasts, and other expectations, the ability to convert design wins into definitive orders and the magnitude of such orders, the ability to identify and realize additional opportunities, potential changes and developments in the highly competitive LiDAR technology and related industries, and our expectations regarding the impact of the evolving conflict in Israel to our ongoing operations. The foregoing list is not exhaustive. You should carefully consider such risk and the other risks and uncertainties described in Innoviz’s annual report on Form 20-F for the year ended December 31, 2024, filed with the U.S. Securities and Exchange Commission (“SEC”) on March 12, 2025 and in other documents filed by Innoviz from time to time with the SEC. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. There can be no assurances that the Company will enter into definitive agreements, orders or receive payments with respect to the program selection referenced in this announcement. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Innoviz assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise. Innoviz gives no assurance that it will achieve its expectations.

To enable SAE Level 4 autonomous driving, the company has purposefully designed and built redundancy into the Freightliner Cascadia platform for safety-critical systems for safe, driverless operations. With over 1,500 engineering requirements, all translated into features, and a second set of electronically controlled systems like an integrated power network, the autonomous-ready Cascadia sets an industry standard for autonomous systems integration. – Daimler Truck press release April 2025

To enable SAE Level 4 autonomous driving, the company has purposefully designed and built redundancy into the Freightliner Cascadia platform for safety-critical systems for safe, driverless operations. With over 1,500 engineering requirements, all translated into features, and a second set of electronically controlled systems like an integrated power network, the autonomous-ready Cascadia sets an industry standard for autonomous systems integration. – Daimler Truck press release April 2025 After 20 years in the robotics business, and six years of software research and development, Torc officially opened the company’s first commercial hub in May 2025, getting our trucks officially on the I-35 corridor. Our fleet has moved from our testing grounds in Albuquerque to focus on the Laredo to Fort Worth route, a crucial freight lane for many large freight customers. We’re already working in concert with them as we continue to look for more opportunities for the latter half of 2026.

After 20 years in the robotics business, and six years of software research and development, Torc officially opened the company’s first commercial hub in May 2025, getting our trucks officially on the I-35 corridor. Our fleet has moved from our testing grounds in Albuquerque to focus on the Laredo to Fort Worth route, a crucial freight lane for many large freight customers. We’re already working in concert with them as we continue to look for more opportunities for the latter half of 2026. There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

There are still technology refinements and milestones to hit for our virtual driver and AI development as well, and we’ll be doing that with our new technology center in Ann Arbor, Michigan. Situated close to closed course test tracks and surrounded by top-notch robotics university programs, we continue to onboard the Torc’rs needed to get to our market entry timeframe.

An accomplished technology leader with more than two decades of experience in semiconductors, edge computing, and automotive systems, Rebeca most recently served as Chief Technology Officer and Senior Principal AI Engineer at Intel Automotive, where she led a diverse, multidisciplinary team in the Automotive CTO Office. In this role, she defined the company’s “whole vehicle” compute strategy, drove AI and high-performance compute innovation, and played a pivotal role in acquisitions and industry standards.

An accomplished technology leader with more than two decades of experience in semiconductors, edge computing, and automotive systems, Rebeca most recently served as Chief Technology Officer and Senior Principal AI Engineer at Intel Automotive, where she led a diverse, multidisciplinary team in the Automotive CTO Office. In this role, she defined the company’s “whole vehicle” compute strategy, drove AI and high-performance compute innovation, and played a pivotal role in acquisitions and industry standards.